CNC Machining Services

In operation since 1983, Rejent’s 15,000 sq. ft manufacturing facility uniquely offers EDM and Surface grinding, along with machining under a single roof. With this range of specialization, customers get faster turn-around, and the comfort of dealing with a single provider.

Rejent’s North American and international clients span oilfield, mining, aerospace, university engineering departments, medical, heavy equipment manufacturers, and the valve industry. Rejent can handle your projects, from prototyping to production runs.

Internal grinding of a carbide sleeve

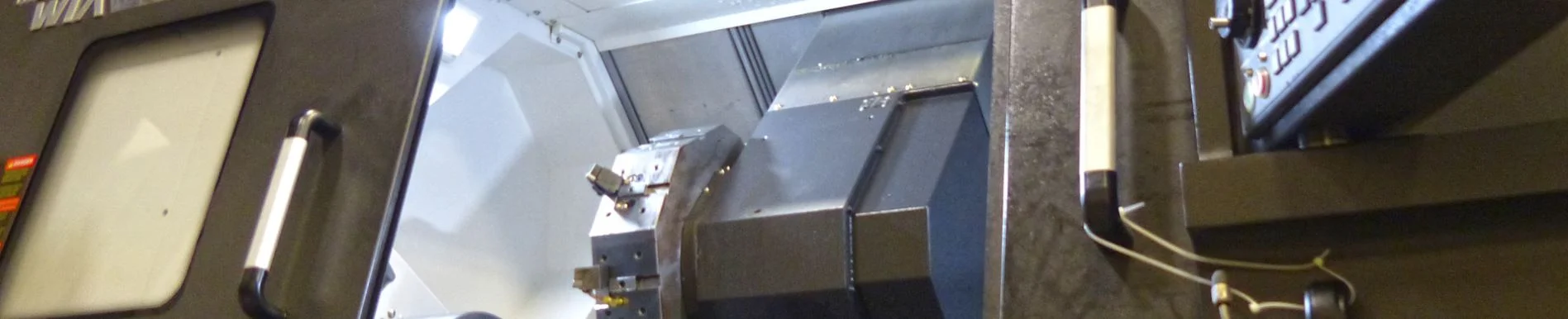

CNC Milling

We use a range of CNC (Computer Numerical Control) Machining and manual machines to provide superior surface finishing and accuracy. Our experienced machinists and operation allows for full CAD / CAM / Solidworks capabilities, fourth and fifth-axis CNC milling. Because of our one-stop shop abilities for CNC milling, machining, EDM, and grinding it makes us highly-suitable for handling jobs throughout North America and abroad.

Largest work envelope 50-inch by 26-inch.

CNC Turning

At Rejent, we have multiple CNC lathes that can process components ranging in size from under an inch in diameter all the way up to 26″ in diameter. We can also process lengths up to 120” in. our advanced laths can work on materials including titanium, inconels, and stainless steel. We can work on highly complex parts with tolerances as low as 0.0005″. We also use manual lathes in our turning department.

The experienced project managers and technicians at Rejent create metal components for the entire spectrum of industrial and commercial industries. We build directly from existing design or work with companies to fabricate custom components.

Lengths up to 120-inch

Swings up to 26-inch.