Online Orders -

SERIES II RTJ GO-NOGO Paddle Gages

RTJ Paddle Gages

Our ring groove paddle gauges designed specifically for the oil & gas industry.

Ring Groove Paddle Gages for BX/RTJ API Ring grooves

Introducing the Rejent Tool & Manufacturing Series II Ring Groove Paddle Gage, an exceptional precision tool crafted specifically for the oil and gas industry. Whether you're on the shop floor or in the field, this product offers a rapid check to ensure compliance with overall groove form. Engineered with utmost precision, our paddle gages are constructed using hardened D2 tool steel, providing unparalleled wear resistance. Employing wire EDM techniques in the manufacturing process guarantees the highest level of accuracy. Explore the extensive range of paddle gages available, available for most API standard ring grooves. Elevate your quality control processes with this top-tier solution!

MEETS INDUSTRY REQUIREMENTS

Easy To Use

Allows checking of groove depth and form

Usable for both in-shop and in-field

Top Quality Materials

GO / NO GO GAGE FOR GROOVE DIAMETERS

This is our most popular manufactured gage, available as a stock item for shipment to all locations. Customers trust this simple to use, accurate ring groove measurement solution in refineries, pumps, and valve applications. For more information about the design and manufacturing of our Series II ring groove gage, or the other specialty products and capabilities we offer please see the table below or contact us directly.

Rejent Series II BX & RTJ GO-NOGO Paddle Gages

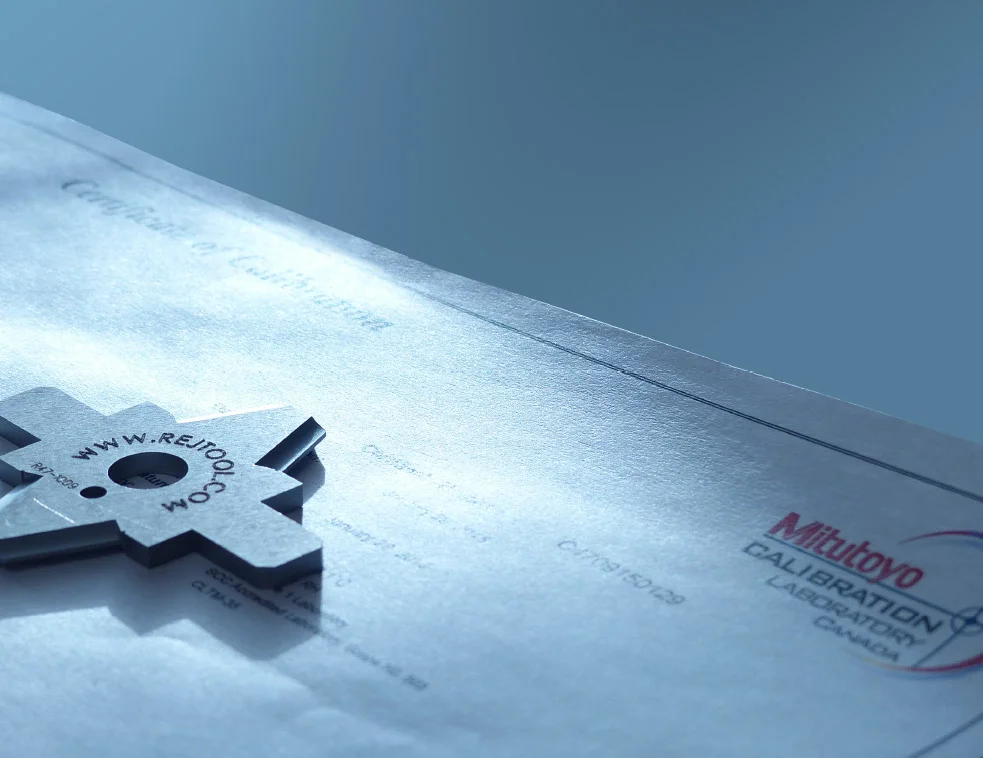

All of our Go / NoGo paddle gages are developed in house and fully certified by Mitutoyo Calibration Laboratory Canada. We have a range of Go / No-go Paddle gages at various dimensions. These gages serve as a useful reference on the manufacturing floor for the depth, taper and width of a given slot to ensure compliance with the API standard.

PRODUCT FEATURES

Hardened Tool Steel

Calibrated by Mitutoyo Labs

Long Form Calibration Sheet included with each gage Perfect for quick inspection on width,form and depth

HOW GO / NO GO GAGES FUNCTION

Our go / no-go gauges are a key part of the quality control process and assist assessment of accepted tolerances. In a matter of seconds an operator can determine if a part is compatible with another part or process.